Engine Valve

We manufacture high-quality engine valves for customers worldwide, meeting the strictest quality standards for petrol, diesel, and alternative fuel engines. Our valves are used across a wide range of applications, including agriculture, automotive, heavy-duty trucks, earthmoving equipment, and marine engines. With a strong and extensive valve database, we offer excellent product range and ready availability. Every valve we produce is made using premium materials and strict quality controls to ensure reliable and long-lasting performance.

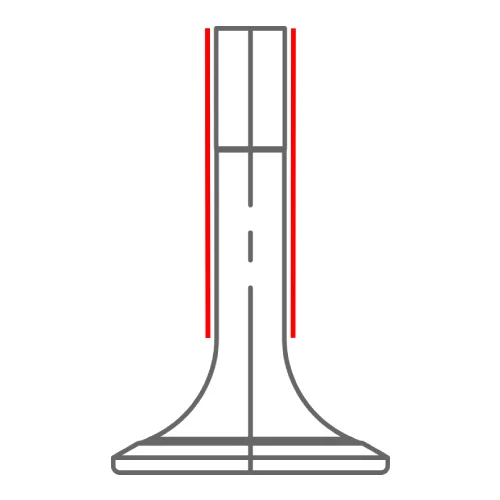

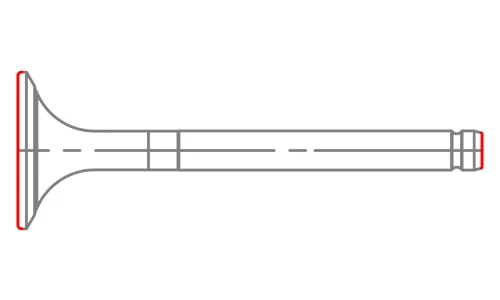

By function, there are only two types of valves, inlet valve and exhaust valve. Inlet valves allow proper mixture of air and fuel to enter in combustion chamber, while exhaust valve opens to escape gases produced after combustion of air and fuel in camber. Inlet valve is exposed to low thermal stress, but exhaust valve has to undergo high thermal and mechanical stress due to its operation under high temperate and pressure.

Generally, inlet valves are made of martensitic steel and exhaust valve are made of austenitic steels or high alloy steel. Based on their design, material and application, valves can be monometallic, entirely fabricated from a single metal, or bimetallic, fabricated using a friction welding process to have properties of austenitic head and martensitic stem.

Martensitic, Austenitic, Super Alloys & Hard Facing Alloys

Monthly Production of 2,00,000+ Pieces with Spare Capacity

Exact Dimensions for perfect fitment

Supplying to After Markets

4000 different types of Inlets and Exhaust Valve

Heat, corrosion & wear resistance

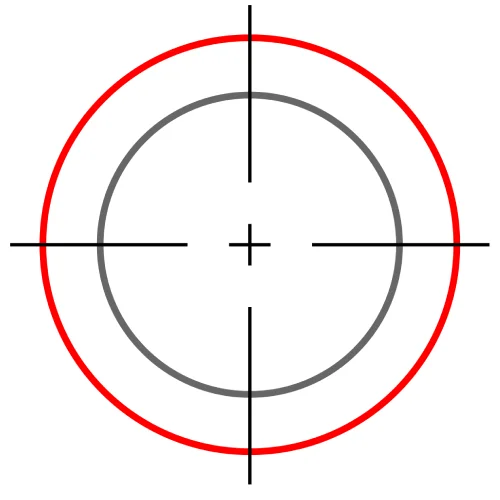

Specifications of Engine Valve

Head 15 to 175 mm

Steam 4 mm to 30 mm

Length 55 mm to 550 mm

Dimension

Overall Length

Stem Diameter

Head Diameter

Stem Tip Length

Concentricity

Hardness (HRC)

Range

55 – 550 mm

4 – 30 mm

15 – 175 mm

4 – 25 mm

240 MPa

48 to 53

Engine Valve

The valve face and seat experience the highest heat during operation. To increase durability, they are often induction-hardened or welded with a cobalt alloy. Valves are also coated with chromium, phosphate, or nitride to improve strength and wear resistance. For a smooth surface and better performance, they are swirl-polished as well.

The valve face seat faces extreme heat during operation. To ensure long service life, it is specially hardened or reinforced with a cobalt alloy. Advanced coatings such as chromium, phosphate, and nitride enhance durability, wear resistance, and performance. Precision swirl polishing delivers a smooth finish for reliable and efficient operation.