Anti Polishing Ring

An Anti-Polishing Ring (APR) is a critical engine component installed at the top of the cylinder liner to protect the liner bore from polishing and excessive wear. During engine operation, carbon deposits can build up on the piston crown and top ring area. As the piston moves, these hard deposits may rub against the liner surface, causing polishing, increased oil consumption, and loss of compression. The anti-polishing ring prevents this by scraping off carbon deposits before they contact the liner bore.

Anti-polishing rings are manufactured from high-strength, wear-resistant materials designed to withstand high temperatures, pressure, and continuous mechanical impact. By maintaining the correct bore surface condition, the ring helps preserve proper lubrication, reduces piston ring wear, and extends overall engine life.

Anti-polishing rings are widely used in high-output diesel engines, heavy-duty trucks, marine engines, and industrial applications where long service life and consistent performance are essential.

Reduces piston ring wear and blow-by

Monthly Production of 20,000+ Pieces with Spare Capacity

Improves engine efficiency and service life

Helps maintain proper oil control and lubrication

Designed for heavy-duty and high-output engines

Prevents liner bore polishing and excessive wear

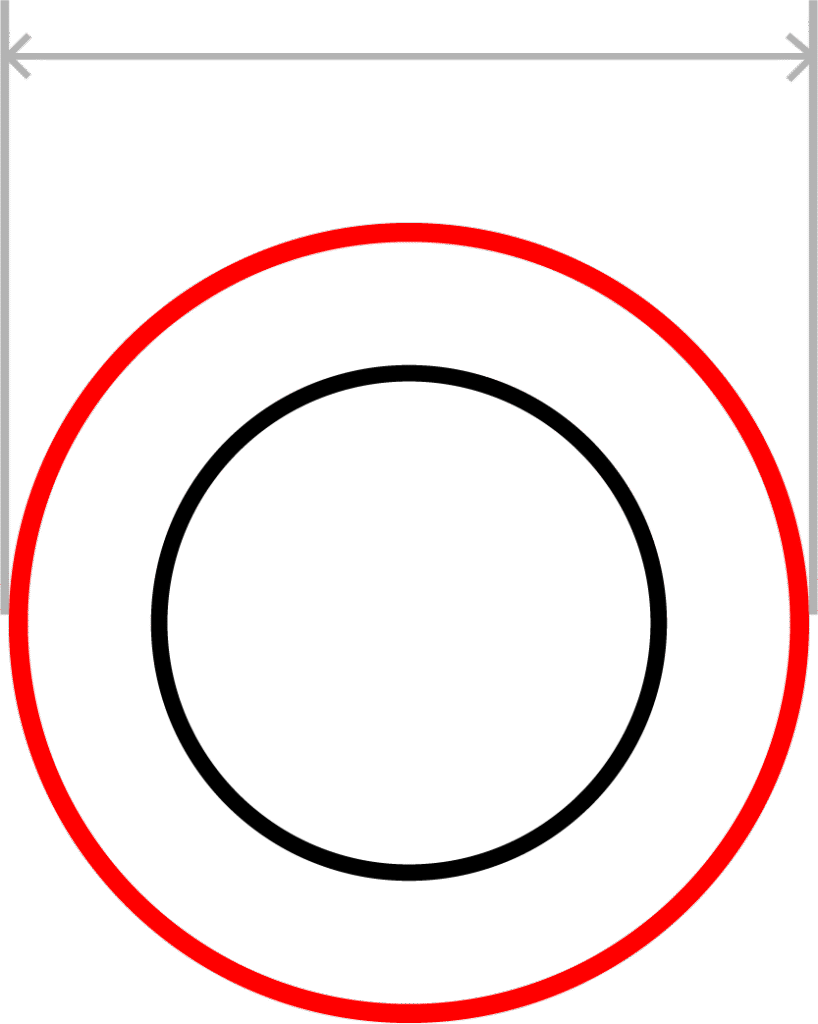

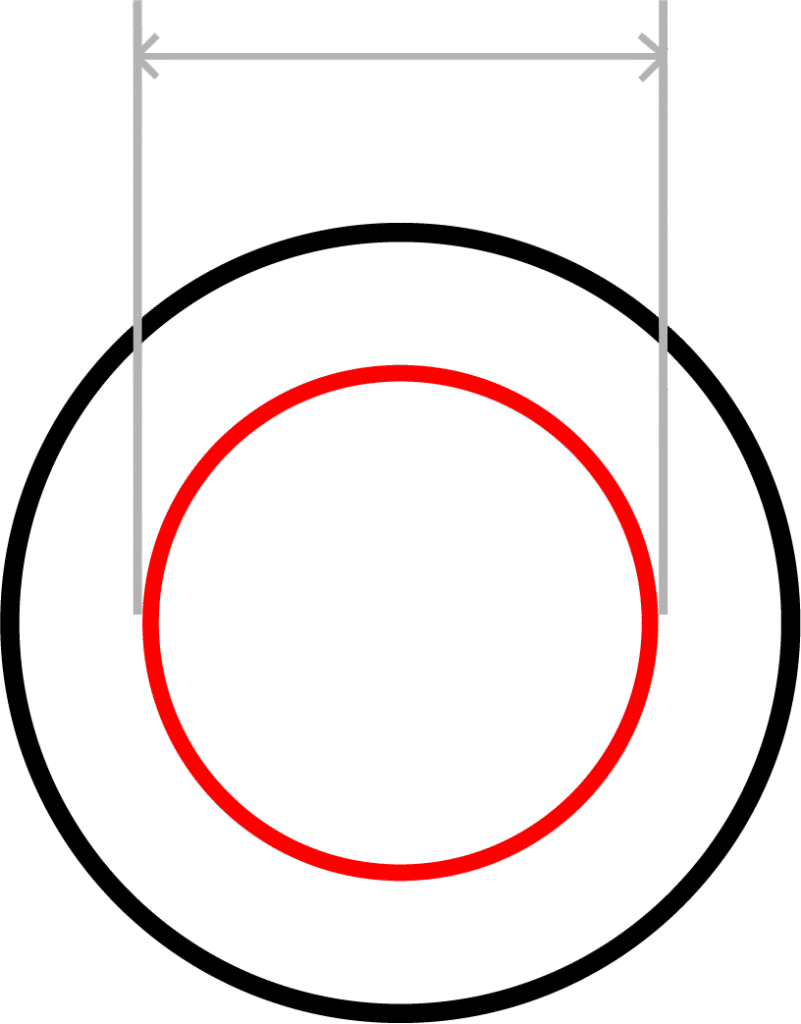

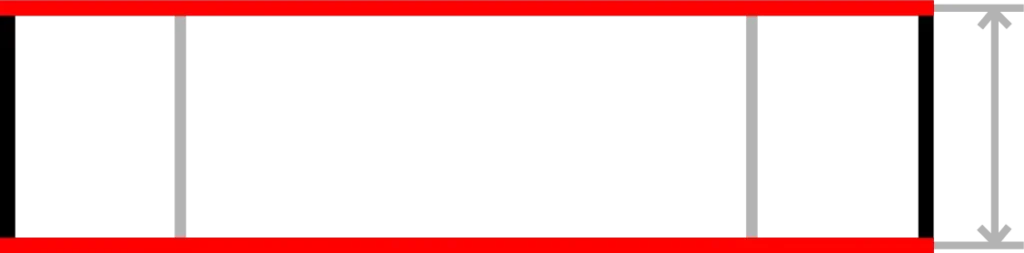

Specifications of Anti Polishing Ring

Outside 120 mm to 500 mm

Inside 100 mm to 550 mm

Height 18 mm to 80 mm

Dimension

Inside

Outside

Height

Groove Length

Groove Depth

Hardness (BHN)

Range

100 – 550 mm

120 - 500 mm

18 - 80 mm

20 - 60 mm

1.5 - 12 mm

180 - 210

Anti Polishing Ring

Engineering begins with selecting high-grade alloy or hardened steel materials that offer excellent wear resistance and thermal stability. The ring geometry is precisely designed to match the piston crown profile and liner dimensions, ensuring effective carbon removal without damaging the liner surface. Tight dimensional tolerances are maintained to achieve accurate fit and consistent scraping performance under all operating conditions.

Manufacturing involves precision machining and controlled heat treatment to achieve the required hardness and durability. Surface finishing is carefully controlled to provide effective carbon removal while minimizing friction. Each anti-polishing ring undergoes strict inspection for dimensional accuracy, hardness, and surface quality to ensure reliable performance and long service life in demanding engine environments.

FAQ

What is the function of an anti-polishing ring?

The anti-polishing ring removes carbon deposits from the piston crown, preventing them from polishing or damaging the cylinder liner bore

Why is an anti-polishing ring important in diesel engines?

Diesel engines produce higher carbon deposits due to high combustion pressure. The anti-polishing ring helps protect the liner and maintain long-term engine performance.

What happens if an anti-polishing ring is not used?

Without an anti-polishing ring, carbon deposits can polish the liner surface, leading to increased oil consumption, reduced compression, and shorter engine life.

Where are anti-polishing rings commonly used?

They are widely used in heavy-duty trucks, marine engines, power generation units, and industrial diesel engines.