Cylinder Liner

A cylinder liner is a critical engine component that forms the inner surface of the engine cylinder, providing a smooth and durable path for the piston to move up and down. It plays a key role in maintaining engine performance, efficiency, and reliability by protecting the engine block from wear, heat, and corrosion. The liner also helps maintain proper compression and ensures efficient combustion inside the engine.

Cylinder liners are manufactured from high-quality cast iron or alloy materials that offer excellent wear resistance, strength, and thermal stability. Advanced metallurgy and controlled heat treatment processes are used to achieve the required hardness and microstructure. The inner bore is precision-machined and honed to provide a smooth surface finish that reduces friction, supports proper lubrication, and minimizes piston ring wear.

Depending on engine design and application, cylinder liners are available in air-cooled, wet, and dry types. Air-cooled liners feature external fins to improve heat dissipation, while wet liners come in direct contact with coolant for efficient temperature control. Dry liners are fitted tightly into the engine block and rely on the block for cooling support. Each type is engineered to meet specific operating conditions and performance requirements.

Strict quality control is maintained throughout the manufacturing process, including dimensional inspection, hardness testing, and surface finish checks. This ensures consistent performance, long service life, and reliable operation even under high loads and extreme temperatures. Designed for petrol, diesel, and alternative fuel engines, our cylinder liners are widely used in automotive, agricultural machinery, heavy-duty trucks, earthmoving equipment, and marine engines worldwide.

Provides a smooth and durable surface for piston movement

Monthly Production of 50,000+ Pieces with Spare Capacity

Protects the engine block from wear and damage

Maintains proper compression and efficient combustion

Precision-machined and honed for reduced friction

Designed for long service life under high temperature and load

Types Of Cylinder Liner

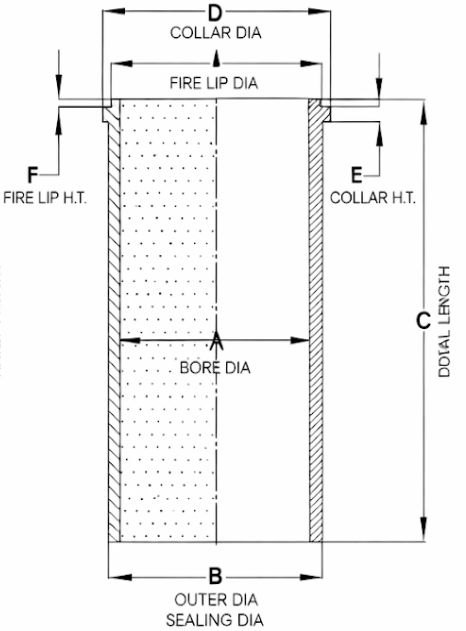

Dry Liner

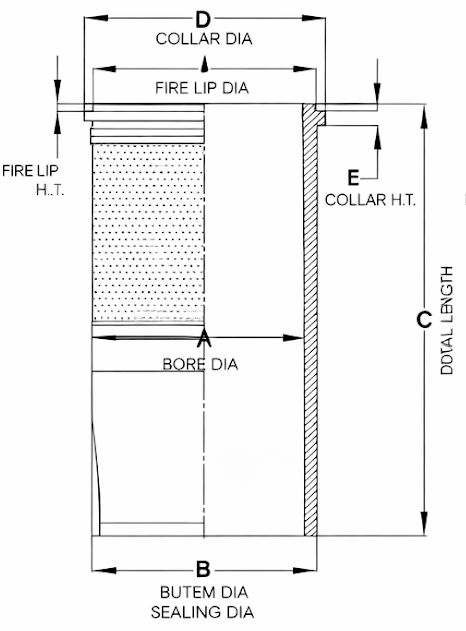

Wet Liner

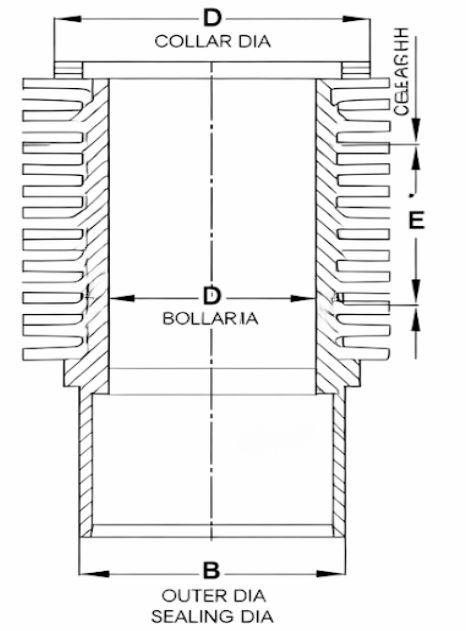

Air Cooled Liner

Specification Of Cylinder Liner

Dimension

Bore Diameter

Total Length

Outer Diameter

Collar Diameter

Concentricity

Hardness (BHN)

Range

50 – 220 mm

90 – 600 mm

55 - 300 mm

60 - 320 mm

≤ 0.03 mm

190 to 280

Cylinder Liner

The engineering process begins with careful material selection based on engine load, operating temperature, and application requirements. High-grade cast iron and alloy materials are engineered to deliver excellent wear resistance, strength, and thermal stability. Metallurgical control ensures uniform grain structure and optimal hardness, which are essential for long service life. Precise design tolerances are maintained to achieve accurate bore geometry, proper piston clearance, and effective heat transfer, ensuring smooth engine operation and reduced friction.

Manufacturing involves advanced machining and controlled heat treatment processes to achieve consistent dimensional accuracy and durability. The inner bore is precision-honed to create an ideal surface texture that supports lubrication and minimizes piston ring wear. For air-cooled liners, fin geometry is engineered for efficient heat dissipation, while wet and dry liners are manufactured for perfect fit and sealing. Each liner undergoes strict inspection for dimensions, hardness, and surface finish, ensuring reliable performance under extreme operating conditions.

FAQ

What is the function of a cylinder liner?

A cylinder liner provides a smooth and durable surface for the piston to move inside the engine cylinder. It protects the engine block from wear, maintains proper compression, and supports efficient combustion.

What materials are used to manufacture cylinder liners?

Cylinder liners are typically made from high-grade cast iron or alloy materials. These materials offer excellent wear resistance, heat tolerance, and long service life under demanding engine conditions.

What are the different types of cylinder liners?

There are three main types of cylinder liners: air-cooled, wet, and dry. Air-cooled liners use external fins for heat dissipation, wet liners are directly cooled by engine coolant, and dry liners are fitted tightly into the engine block.

What happens if a cylinder liner wears out?

A worn cylinder liner can cause loss of compression, increased oil consumption, reduced engine performance, and higher emissions. Replacing the liner helps restore engine efficiency and reliability.