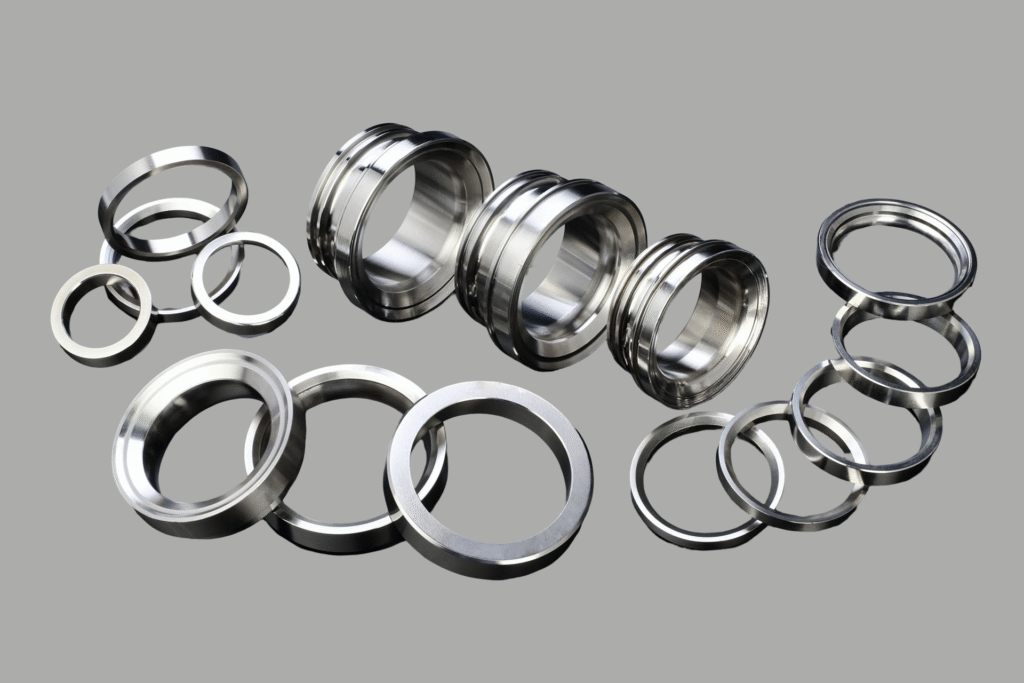

Valve Seat

The valve seat is a vital engine component that directly affects performance, efficiency, and engine life. It provides a precise sealing surface between the valve and the cylinder head, ensuring proper compression and controlled combustion inside the engine. During operation, the valve seat is exposed to extreme heat, high pressure, and continuous mechanical impact, making strength and durability essential. A well-designed valve seat not only prevents gas leakage but also helps transfer heat from the valve to the cylinder head, protecting the engine from overheating.

Our valve seats are manufactured using high-grade alloy materials that offer excellent heat resistance, wear resistance, and strength. In high-temperature applications, special alloys such as cobalt-based materials are used to improve durability and extend service life. Advanced heat-treatment processes further enhance hardness and resistance to deformation under extreme operating conditions.

To ensure reliable performance, every valve seat is machined with high precision for perfect fit and accurate contact with the valve face. This precision helps reduce valve leakage, improves fuel efficiency, and minimizes engine emissions. A smooth and controlled surface finish also reduces wear, ensuring long-lasting sealing performance even in demanding environments.

Precision-machined for perfect fit

Monthly Production of 2,50,000+ Pieces with Spare Capacity

Tested for strength, hardness, and accuracy

Suitable for OEM and aftermarket applications

Made from high-grade, wear-resistant alloys

Heat, corrosion & wear resistance

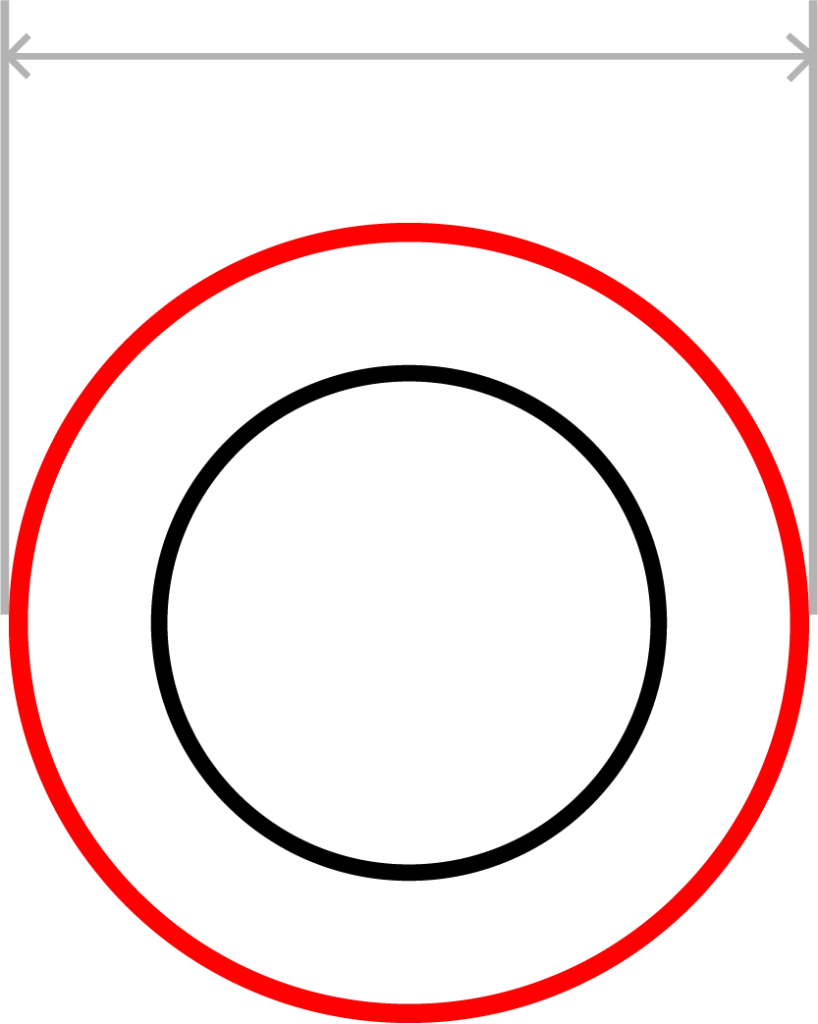

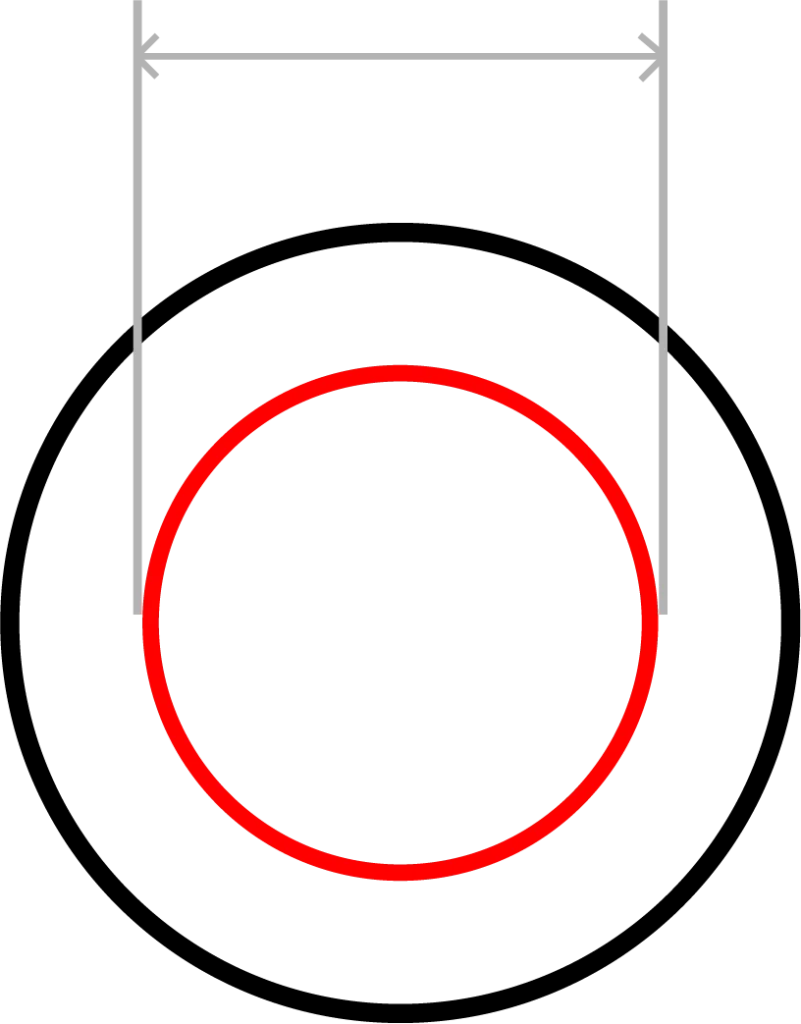

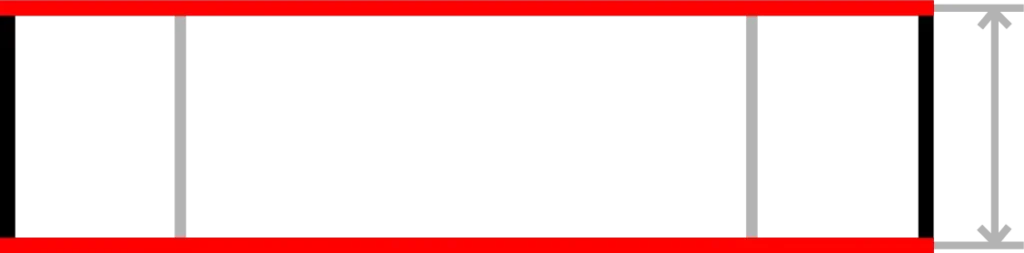

Specifications of Valve Seat

Outer Dia 18 mm to 150 mm

Inner Dia 8 mm to 125 mm

Height 6 mm to 80 mm

Dimension

Outer Diameter

Inner Diameter

Height

Hardness (HRC)

Concentricity

Range

18 - 150 mm

8 – 125 mm

6 - 80 mm

032 to 55

≤ 0.02 mm

Valve Seat

Valve seat engineering begins with a deep understanding of engine operating conditions, including extreme temperatures, high combustion pressure, and continuous mechanical impact. Material selection is carefully engineered based on engine type and application, using high-grade alloy or cobalt-based materials to ensure strength, wear resistance, and thermal stability. Precise design tolerances are maintained to achieve optimal valve contact, efficient heat transfer, and long-term sealing performance. This engineering focus helps prevent valve leakage, seat recession, and premature engine wear.

The manufacturing process combines advanced machining, heat treatment, and finishing technologies to deliver consistent and reliable valve seats. Each component is precision-machined to exact dimensions, followed by controlled heat treatment to enhance hardness and durability. Final surface finishing ensures smooth contact between the valve and seat, reducing friction and extending service life. Strict quality inspections at every stage guarantee dimensional accuracy, material integrity, and performance reliability, resulting in valve seats that meet global OEM and aftermarket standards.

FAQ

What is the function of a valve seat?

The valve seat provides a tight seal between the valve and the cylinder head. This seal ensures proper compression, efficient combustion, and smooth heat transfer from the valve to the engine head.

Why is the valve seat material important?

Valve seats operate under high heat and pressure. Using high-grade alloy materials improves wear resistance, heat tolerance, and service life, ensuring reliable performance in demanding engine conditions.

What happens if a valve seat wears out?

A worn valve seat can cause loss of compression, reduced engine power, higher fuel consumption, and increased emissions. Timely replacement helps maintain engine efficiency and reliability.

Are valve seats suitable for different engine types?

Yes, valve seats are designed for petrol, diesel, and alternative fuel engines and are widely used in automotive, agricultural, heavy-duty, earthmoving, and marine applications.