Valve Guide

Valve guides operate under high temperatures, constant friction, and repeated mechanical stress. To withstand these demanding conditions, they are manufactured from high-quality materials such as alloy cast iron, phosphor bronze, or other wear-resistant alloys. These materials provide excellent durability, thermal conductivity, and resistance to scuffing. Effective heat transfer through the valve guide helps dissipate heat from the valve stem to the cylinder head, protecting the valve from overheating.

A valve guide is a crucial engine component that supports and guides the valve stem as it moves up and down during engine operation. Its main function is to maintain accurate alignment between the valve and the valve seat, ensuring proper sealing, efficient combustion, and smooth engine performance. By controlling valve movement, the valve guide reduces side forces on the valve stem and prevents uneven wear.

Precision machining and tight dimensional control are essential in valve guide manufacturing. Accurate internal bore finish ensures smooth valve movement and proper lubrication, reducing friction and oil consumption. A well-engineered valve guide improves valve life, maintains compression, supports low emissions, and enhances overall engine reliability. Valve guides are widely used in petrol, diesel, and alternative fuel engines across automotive, agricultural, heavy-duty, earthmoving, and marine applications.

Guides the valve for smooth and accurate movement

Monthly Production of 1,80,000+ Pieces with Spare Capacity

Maintains proper valve alignment with the valve seat

Ensures efficient heat transfer from valve to cylinder head

Improves engine performance and service life

Manufactured from high-quality, wear-resistant materials

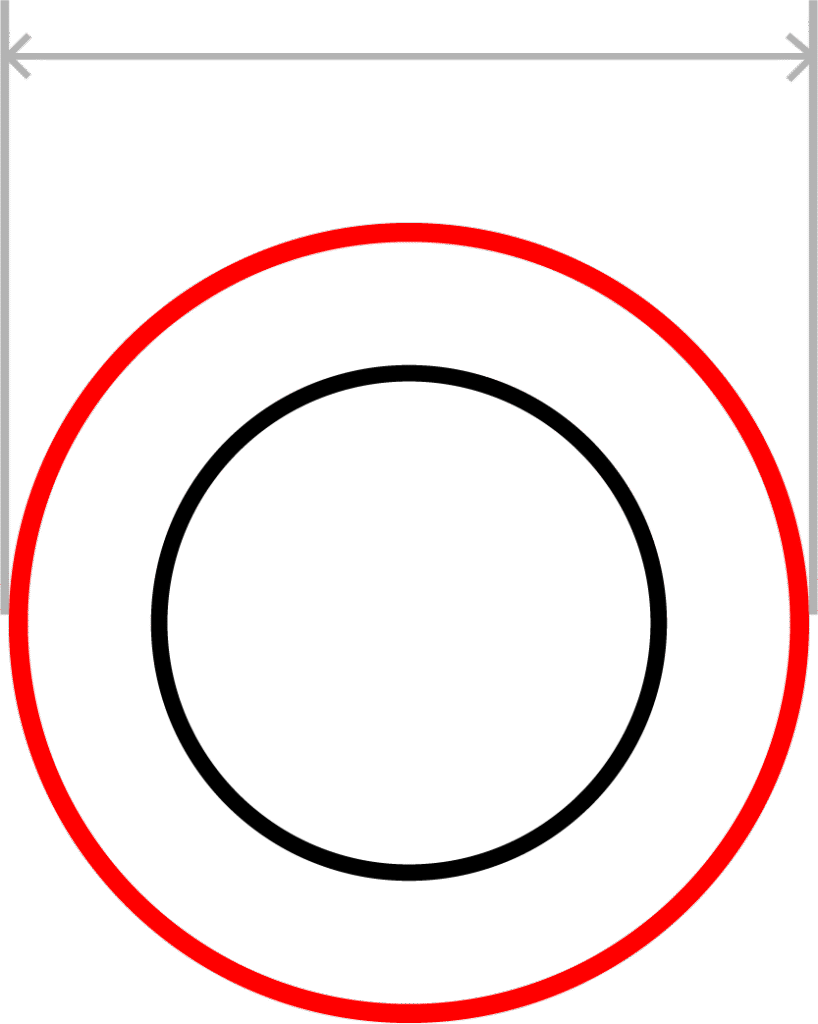

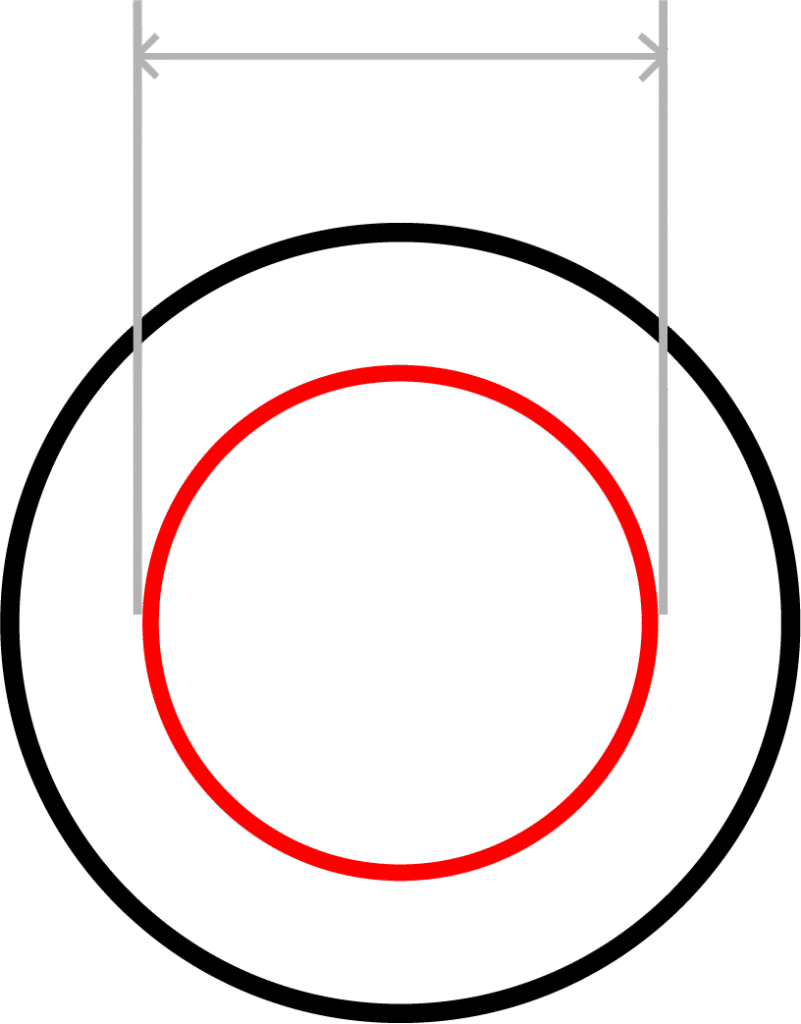

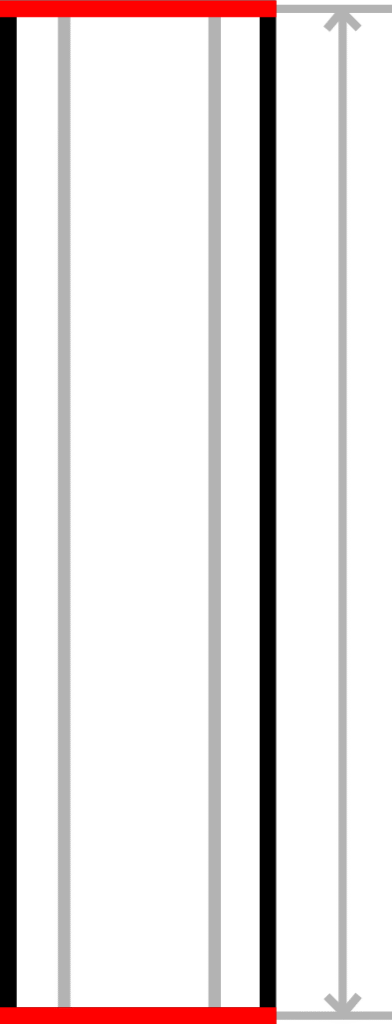

Specifications of Valve Guide

Outer Diameter 7 mm to 40 mm

Inner Diameter 4 mm to 35 mm

Length 25 mm to 300 mm

Dimension

Outer Diameter

Inner Diameter

Length

Material

Concentricity

Hardness (HRB)

Range

7 - 40 mm

4 – 35 mm

25 - 300 mm

C.I.I and Bronze

≤ 0.01 mm

80 to 110

Valve Guide

Engineering starts with selecting the right material composition based on engine load, temperature, and operating conditions. Advanced metallurgy ensures controlled hardness, uniform microstructure, and resistance to wear and thermal distortion. Design tolerances are carefully engineered to maintain correct piston clearance, bore geometry, and heat transfer efficiency, ensuring smooth engine operation and durability.

Manufacturing involves advanced machining, heat treatment, and precision honing to achieve accurate dimensions and surface finish. For air-cooled liners, fin design is engineered for efficient heat dissipation, while wet and dry liners are produced for perfect fit and sealing. Each liner undergoes strict inspection for dimensional accuracy, hardness, and surface quality to meet global OEM and aftermarket standards.

FAQ

What is the function of a valve guide?

A valve guide supports and aligns the valve stem, allowing smooth movement during engine operation while maintaining proper contact with the valve seat.

Why is valve guide material important?

Valve guides operate under high temperature and friction. High-quality materials ensure wear resistance, heat transfer, and long service life.

What happens if a valve guide wears out?

Worn valve guides can cause oil consumption, poor valve sealing, reduced engine performance, and increased emissions.

Are valve guides used in different engine types?

Yes, valve guides are designed for petrol, diesel, and alternative fuel engines and are widely used in automotive, agricultural, heavy-duty, and marine applications.